6/4DG gravel pump

Product Features

Type G(orGH) gravel pumps are designed for continuously handling the most difficult high abrasive slurries which contain too big solids to be pumped by a common pump. They are suitable for delivering slurries in Mining, Explosive sludge in metal melting, Dredging in dredger and river course, and other fields. Type GH are high head pumps.

Construction

Construction of this pump is of single casing connected by means of clamp bands and wide wet-passage. The wet-parts are made of Ni_hard and high chromium abrasion-resistance alloys. The discharge direction of pump can be oriented in any direction of 360°. This type of pump possesses the advantages of easy installation and operation, good performance of NPSH and abrasion-resistance.

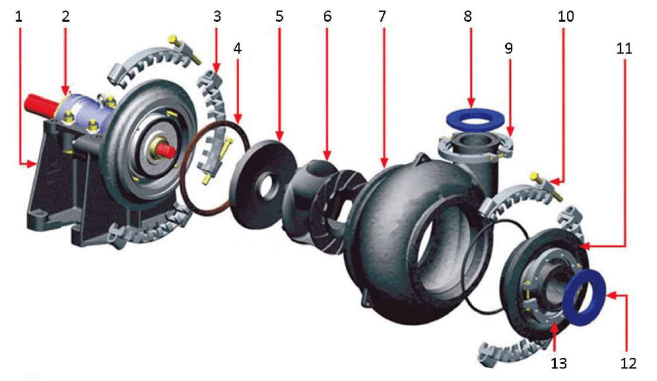

1.Support 8. Discharge Joint Ring

2.Bearing Housing Assembly 9. Discharge Flang

3.Adapter Plate Clamp Band 10. Door Clamp Band

4.Volute Liner Seal 11. Cover Plate

5.Frame Plate Liner Insert 12. Intake joint ring

6. Impeller 13. Intake flange

7. Frame Plate / Bowl 14. Adapter plate

Performance Chart

| Pump Model | Allowable Max. Power (kw) |

Clear Water Performance | ||||||

| Capacity Q | Head H (m) |

Speed n(r/min) |

Max.Eff. (%) |

NPSH (m) |

Impeller. Dia. (mm) | |||

| m3/h | l/s | |||||||

| 6/4D-G | 60 | 36-250 | 10-70 | 5-52 | 600-1400 | 58 | 2.5-3.5 | 378 |

| 8/6E-G | 120 | 126-576 | 35-160 | 6-45 | 800-1400 | 60 | 3-4.5 | 378 |

| 10/8S-GH | 560 | 216-936 | 60-260 | 8-52 | 500-1000 | 65 | 3-7.5 | 533 |

| 10/8S-G | 560 | 180-1440 | 50-400 | 24-30 | 500-950 | 72 | 2.5-5 | 711 |

| 12/10G-G | 600 | 360-1440 | 100-400 | 10-60 | 400-850 | 65 | 1.5-4.5 | 667 |

| 12/10G-GH | 1200 | 288-2808 | 80-780 | 16-80 | 350-700 | 73 | 2.0-10.0 | 950 |

| 14/12G-G | 1200 | 576-3024 | 160-840 | 8-70 | 300-700 | 68 | 2.0-8.0 | 864 |

| 16/14G-G | 600 | 720-3600 | 200-1000 | 18-44 | 300-500 | 70 | 3.0-9.0 | 1016 |

| 16/14TU-G | 1200 | 324-3600 | 90-1000 | 26-70 | 300-500 | 72 | 3.0-6.0 | 1270 |

| 18/16TU-G | 1200 | 720-4320 | 200-1200 | 12-48 | 250-500 | 72 | 3.0-6.0 | 1067 |

Applications

The gravel pump is used for river course, reservoir desalting, coastal reclamation, stretching, deep-sea mining and tailing acquisition etc. Gravel pumps are designed for continuously handling the most difficult higher abrasive slurries which contain too big solids to be pumped by a common pump. They are suitable for delivering slurries in Mining, Explosive sludge in metal melting, Dredging in dredger and course of rivers, and other fields.

6/4DG gravel pump Related Video: